Annealing Furnace Process

The annealing furnace process is a crucial heat treatment used to modify the physical and sometimes chemical properties of materials like metals and glass, enhancing their ductility and reducing hardness for better workability. It encompasses three main phases: recovery, recrystallization, and grain growth, each vital for attaining the desired material traits.

Recovery Stage: The furnace raises the temperature to relieve internal stress.

Recrystallization Stage: The Furnace heats the substance above its recrystallization temperature and below its melting point, effectively resetting its internal structure. The specific temperatures vary by material.

Grain Growth Stage: New grains develop as the material cools, making it more pliable. Slow cooling is preferred for larger grain growth.

As a professional annealing furnace manufacturer, we are committed to providing high-quality wire annealing furnaces, helping you achieve the desired balance of strength, ductility, and other material properties through careful control of temperature, atmosphere, and timing.

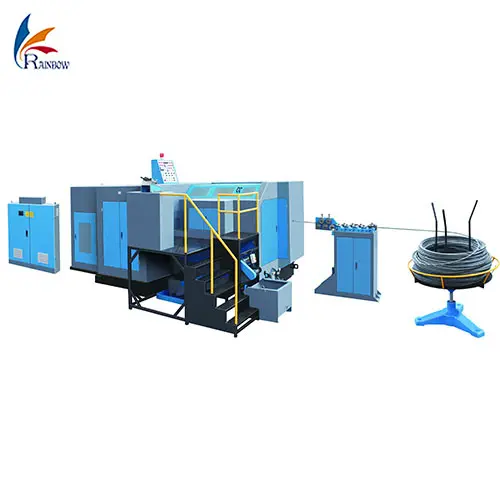

Annealing Furnace Design

An annealing furnace is a kind of equipment used for heat treatment, through the heating and cooling of metal materials, so that it can achieve certain physical properties, such as softening, stress relief, change the crystal structure. The annealing furnace is usually composed of a heating furnace body, temperature control system, feeding and discharging system, etc. The working principle is to place the metal material in the heating furnace body to reach a predetermined temperature and time, and then cool it according to certain rules.

Why Choose Rainbow Annealing Furnace?

1. Years of focus on industrial furnaces, heat treatment furnace research and development, and design.

2. Has a professional design, production team, processing, installation, and after-sales one-stop service.

3. Strictly comply with the contract design and production, tailor-made to provide worry free, convenient and stable industrial furnace solutions.

English

English français

français Español

Español русский

русский português

português