Features of 4 Spindle Nut Tapping Machine

A nut tapping machine is a type of mechanical processing equipment designed to create internal threads, screws, or teeth inside holes of various specifications, such as those found in nuts and flanges. These machines can handle both through holes and blind holes. Depending on the number of spindles, nut tapping machines can be classified into single-axis nut tappers, dual-axis nut tappers, four-axis nut tappers, six-axis nut tappers, etc.

The automatic nut tapping machine offers the highest level of automation. Simply placing the nut blanks into the hopper, the nut threading machine can automatically feed, position, clamp, tap, and unload the nuts. This high degree of automation allows a single worker to operate multiple machines simultaneously, significantly boosting production efficiency and reducing labor costs.

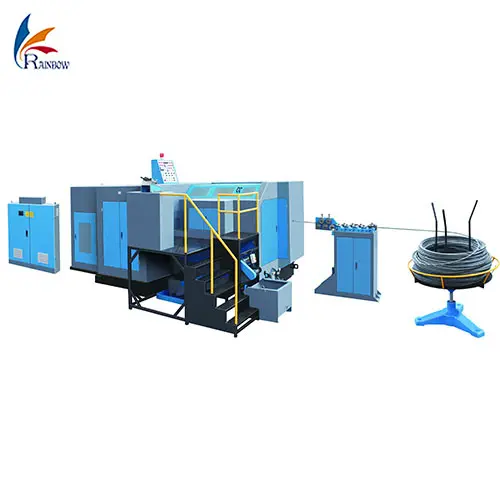

Rainbow's nut tapping machine has the characteristics of novel design, reasonable structure, easy to use, high degree of automation, easy to use, high efficiency, maintenance-free, and extremely high cost performance. The various nut threads processed by the high-quality nut tapping machine have high finish, and the qualified rate of the finished product can reach 100%.

How Does 4 Spindle Nut Tapping Machine Reduce Material Waste?

To reduce material waste when using a 4 Spindle Nut Tapping Machine, consider implementing the following strategies:

Ensure that the nut tapping machine is set up correctly for the specific nut size and thread requirements. Properly program the machine to minimize unnecessary tool movements and material removal.

Use the appropriate tooling and cutting parameters for the specific material being processed to minimize excess material removal.

Choose the right material for your nuts. Using materials with appropriate dimensions and quality can reduce the need for extensive machining and minimize waste.

Consider using pre-cut or pre-formed blanks that are closer in size and shape to the final product, reducing the amount of material that needs to be removed.

Implement strict quality control measures to detect and address defects early in the production process. This helps reduce the number of rejected parts and wasted materials.

Regularly inspect the nut tapper machine for signs of wear and ensure that it is properly calibrated to prevent errors that can result in material waste.

Collect and recycle any scrap material generated during the tapping process. This can include shavings and off-cuts.

Consider implementing a scrap material management system to separate and recycle materials efficiently.

Optimize the tapping process for efficiency. Minimize idle times and non-productive movements of the nut tapper machine.

Implement lean manufacturing principles to reduce setup times, changeovers, and downtime, which can all contribute to material waste.

By implementing these strategies, you can reduce material waste when using a 4 Spindle Nut Tapping Machine, leading to cost savings and a more environmentally friendly production process.

English

English français

français Español

Español русский

русский português

português