-

Products

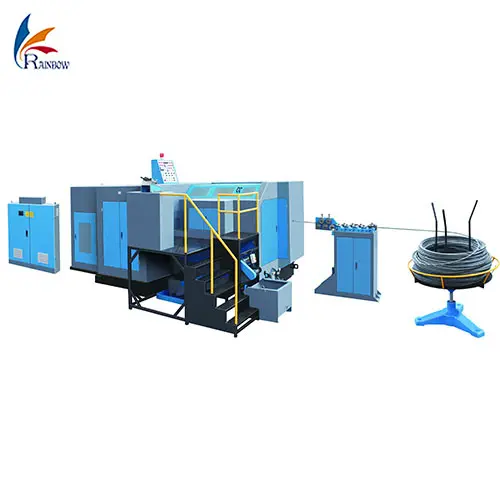

Wire Drawing Machine Inverted Vertical Wire Drawing Machine Fine Wire Drawing Machine Combined Wire Drawing Machine LZ2/800+LT8-13/650 Heavy Wet Wire Drawing Machine LT8.11.13.15.17/450-650 Straight Line Wire Drawing Machine LZ9/1200+Spool Take-up Machine GS 1250 OTO Type Wire Drawing Machine LW9/560 Turnover Wet Wire Drawing Machine Belt Wire Drawing Machine

- Application

- Company

- Services

- Resources

- News

Contact

English

English français

français Español

Español русский

русский português

português