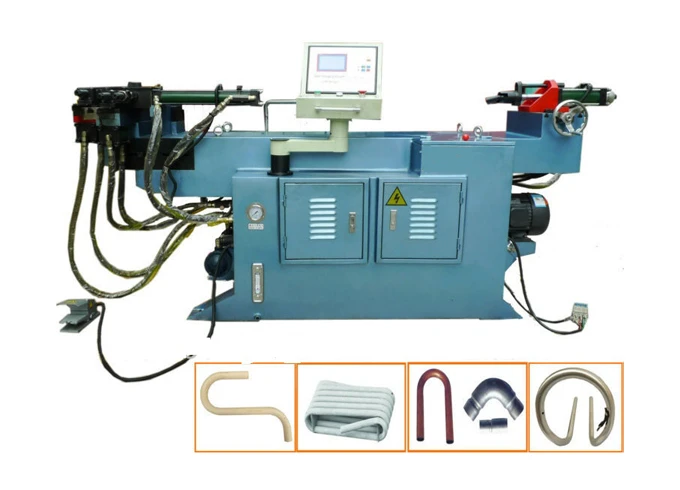

Working Principles of XM-B38NC Spline Head Hydraulic Pipe Bending Machine

XM-B38NC Spline Head Hydraulic Pipe Bending Machine operates based on the principles of hydraulic power and controlled motion to precisely bend pipes into various shapes. Here's a simplified overview of its working principles:

1. Material Feeding: The process begins with a straight pipe or tube being fed into the machine. The pipe's diameter, material type, and desired bend angle are pre-programmed into the machine's control system.

2. Clamping: The pipe is securely clamped in place using hydraulic clamps or other holding mechanisms to prevent it from moving during the bending process.

3. Hydraulic Cylinder: The heart of the machine is the hydraulic cylinder, which is responsible for generating the force needed to bend the pipe. Hydraulic fluid is pressurized and sent to the cylinder.

4. Bending Die and Mandrel: The bending die, which matches the desired bend radius, is positioned around the pipe at the point where the bend is to be created. In some cases, a mandrel (a rod inserted into the pipe) is used to prevent wrinkling or collapsing of the inner wall during the bend.

5. Hydraulic Pressure: As hydraulic fluid is applied to the hydraulic cylinder, it exerts force on the pipe, causing it to bend around the die. The hydraulic pressure can be precisely controlled to achieve the desired bend angle.

6. Bending Motion: The hydraulic cylinder, driven by the hydraulic pressure, moves the pipe along the bending die, creating a smooth, controlled bend. The bending process is carefully monitored by sensors and the machine's control system.

7. Release and Unclamping: Once the desired bend angle is achieved, the hydraulic pressure is released, and the clamps are opened, allowing the bent pipe to be removed from the machine.

8. Quality Inspection: The bent pipe is typically inspected for accuracy and quality to ensure it meets the specified tolerances and standards.

English

English français

français Español

Español русский

русский português

português