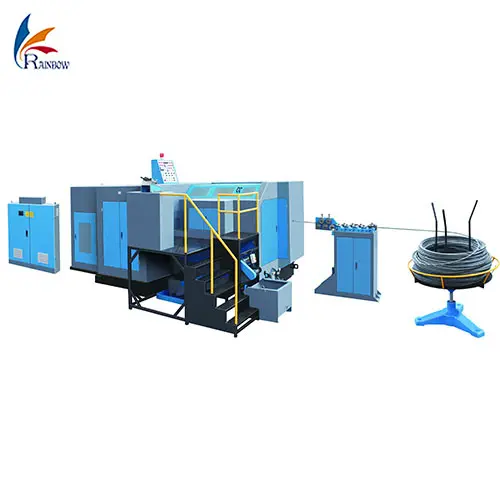

Specifications of HSD-30 Bi-metal Rivet Machine

| No. | Item | Unit | Data |

| 1 | Power of the electormotor | KW | 2.2 |

| 2 | Shear licing intensity | Mpa | ≥98 |

| 3 | Weight of the machine | Kg | 1100 |

| 4 | Diameter of the rivet's head | mm | 2.5-6 |

| 5 | Diameter of the rivet's shank | mm | 1.2-3 |

| 6 | Diameter of the plate product | mm | 3-6 |

| 7 | Output | pcs/min | 0-130 |

All specifications Mre subject to changes wnthout pricr Dotice

Applications of HSD-30 Bi-metal Rivet Machine in Automotive Industry

The HSD-30 Bi-metal Rivet Machine has several applications in the automotive industry due to its ability to securely attach bi-metal rivets. Here are four key applications:

1. Automotive Body Assembly: Bi-metal rivets are used in the assembly of automotive bodies to join various components securely. The HSD-30 machine can be employed to attach rivets that join panels, brackets, and structural components, ensuring the structural integrity of the vehicle.

2. Exhaust System Manufacturing: In the production of exhaust systems, bi-metal rivets are used to attach components like hangers, brackets, and heat shields. The HSD-30 machine facilitates the efficient and reliable attachment of these critical parts.

3. Suspension and Chassis Components: Bi-metal rivets are used to connect suspension and chassis components, including control arms, subframes, and crossmembers. The HSD-30 machine ensures the secure attachment of these components, contributing to vehicle stability and safety.

4. Interior and Trim Assembly: The automotive interior requires various components to be securely attached, including trim pieces, panels, and brackets. The HSD-30 machine can be used to attach bi-metal rivets in these applications, ensuring a neat and durable interior finish.

In each of these applications, the HSD-30 Bi-metal Rivet Machine plays a crucial role in the automotive manufacturing process, contributing to the quality, durability, and safety of the final vehicles.

English

English français

français Español

Español русский

русский português

português