Materials Used in Punches Manufacturing

The materials commonly used in punch manufacturing include:

1. High-Speed Steel (HSS): HSS is a common material due to its excellent combination of hardness, wear resistance, and toughness. It can withstand high temperatures and maintain its properties even at high speeds and high cutting forces.

2. Tool Steel: Tool steels, such as D2, A2, and O1, are widely used for punches. They offer good hardness, toughness, and wear resistance, making them suitable for various applications.

3. Carbide: Carbide punches are known for their exceptional hardness and wear resistance. They are often used for high-volume production or when working with abrasive materials.

4. Powdered Metals: Punches made from powdered metals, such as powdered tool steels or tungsten carbide, offer improved durability and wear resistance.

5. High-Speed Steel with Coatings: Some punches are made from high-speed steel and then coated with materials like TiN (Titanium Nitride), TiCN (Titanium Carbonitride), or DLC (Diamond-Like Carbon) to enhance hardness, lubricity, and resistance to wear and corrosion.

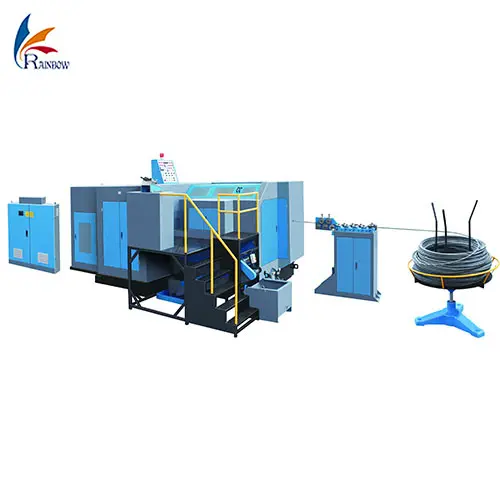

The choice of material depends on factors such as the type of application, the material being punched, the expected load, and the desired tool life. Die punch manufacturers Rainbow will carefully select the most suitable material to ensure that punches meet the performance demands of their intended applications.

English

English français

français Español

Español русский

русский português

português