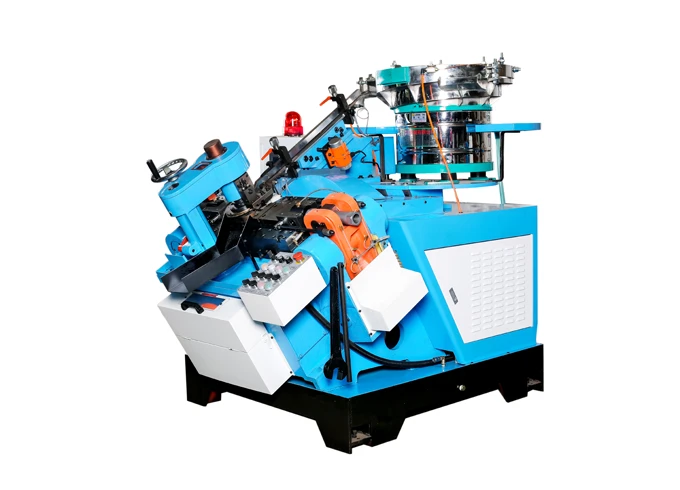

Functions of HSGT2-5-40-End Cutting Machine

The HSGT2-5-40-End Cutting Machine is designed for specific cutting applications in manufacturing processes. Here are five functions of this machine:

1. Precision Cutting: The primary function of the HSGT2-5-40-End Cutting Machine is to perform precise cutting of various materials, such as rods, pipes, wires, and profiles. It ensures accurate and clean cuts, maintaining tight tolerances and minimizing material waste.

2. High Production Throughput: This machine is designed for high-speed cutting operations, allowing for rapid and efficient processing of materials. It is suitable for manufacturing environments where productivity is crucial.

3. Versatile Cutting Angles: The HSGT2-5-40-End Cutting Machine often provides the capability to cut materials at different angles, facilitating the production of components with specific angular requirements. This versatility is valuable in various industries.

4. Automatic Feeding and Ejection: Many models of end cutting machines are equipped with automatic feeding and ejection systems. These features streamline the cutting process, reduce manual handling, and enhance overall efficiency.

5. Customizable Cutting Parameters: Operators can often adjust cutting parameters such as feed rates, cutting speed, and blade pressure to accommodate different materials and cutting requirements. This customization ensures optimal results for various applications.

Overall, the HSGT2-5-40-End Cutting Machine plays a vital role in manufacturing by providing precise, high-speed cutting capabilities with versatility for different materials and cutting angles. It contributes to efficient production processes and the production of components with consistent quality.

English

English français

français Español

Español русский

русский português

português