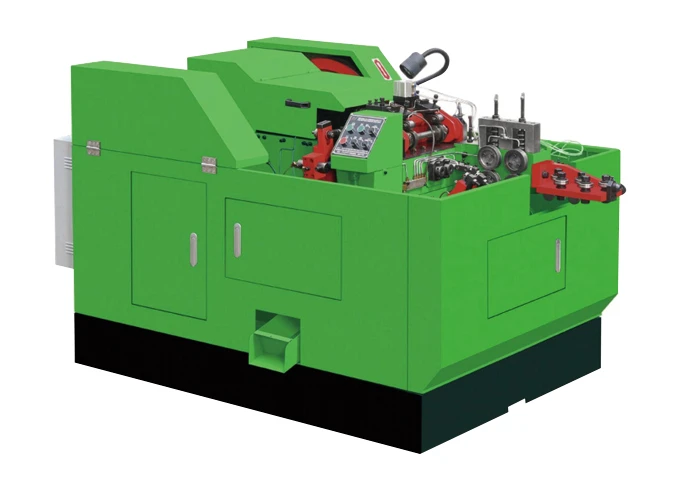

Specifications of RB Series 2 Die 4 Blow Cold Heading Machine

| Model | Cut off Die Diameter/mm | Punch Die Diameter/mm | Cutter Size/mm | Main Motor Power/kw | Volume(L*W*H)/m | Weight/kg | Cut off Die Diameter/mm | Punch Die Diameter/mm | Cutter Size/mm | Main Motor Power/kw | Volume(L*W*H)/m | Weight/kg |

|

|

| RB2415 | Ф19X35 | Ф31X72X4 | 10X32X80 | 5.5HP/4.0KW | 23X13X12 | 2600 | Ф19X35 | Ф31X72X4 | 10X32X80 | 5.5HP/4.0KW | 23X13X12 | 2600 |

| RB2420 | Ф22X40 | Ф35X80X4 | 12X40X85 | 7.5HP/5.5KW | 24X1.25X16 | 4050 | Ф22X40 | Ф35X80X4 | 12X40X85 | 7.5HP/5.5KW | 24X1.25X16 | 4050 |

| RB2425 | Ф35X50 | Ф38X120X4 | 14X45X105 | 24HP/15KW | 4.1X175X179 | 6750 | Ф35X50 | Ф38X120X4 | 14X45X105 | 24HP/15KW | 4.1X175X179 | 6750 |

| RB2430 | Ф38X50 | Ф50X130X4 | 16X50X125 | 20HP/18KW | 4.05X18X19 | 8300 | Ф38X50 | Ф50X130X4 | 16X50X125 | 20HP/18KW | 4.05X18X19 | 8300 |

| RB2440 | Ф45X55 | Ф58X150X4 | 20X65X125 | 30HP/22KW | 5X19X19 | 15600 | Ф45X55 | Ф58X150X4 | 20X65X125 | 30HP/22KW | 5X19X19 | 15600 |

All specifications are subject to changes without prior notice

How Does RB Series 2 Die 4 Blow Cold Heading Machine Work?

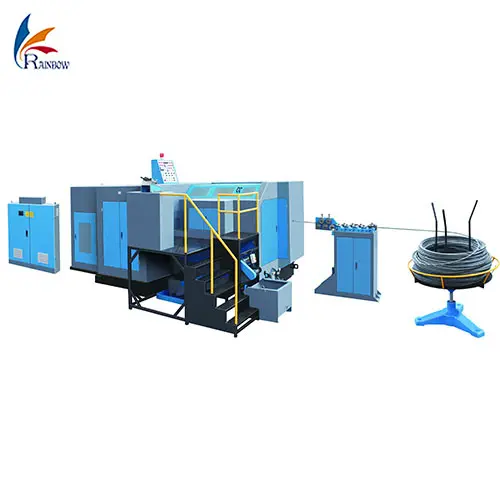

1. Material Feeding: Initially, metal wire or rod stock is loaded into the machine. This raw material typically comes in the form of coils or straight lengths.

2. Cutting: The cold heading machine cuts the metal into individual blanks or pieces of the required length. This cutting operation is usually performed by a shear or cutoff die.

3. Transfer to Dies: The cut blanks are then automatically or manually transferred to the die stations. In the case of the RB Series 2 Die 4 Blow machine, there are two sets of dies, each with two blows, for a total of four blows.

4. First Blow: In the first die station, the metal blank is placed between two die halves. The dies close in on the blank, subjecting it to a powerful blow. This initial blow shapes the metal partially, often creating a basic form.

5. Transfer to the Second Die Station: After the first blow, the partially formed workpiece is moved to the second die station.

6. Second Blow: In the second die station, another set of dies closes in on the workpiece and delivers a second powerful blow. This further refines the shape of the part.

7. Third and Fourth Blows: For RB Series 2 Die 4 Blow machines, the workpiece is then transferred back to the first die station for a third blow and then to the second die station for a fourth blow. These additional blows allow for even greater precision and complexity in shaping the metal.

8. Ejection: Once all blows are completed, the finished part is ejected from the machine. It is now ready for further processing, such as threading or additional machining if necessary.

This fastener making machinery continues to cycle, repeating these steps for each new metal blank fed into it, ensuring efficient and consistent production.

English

English français

français Español

Español русский

русский português

português