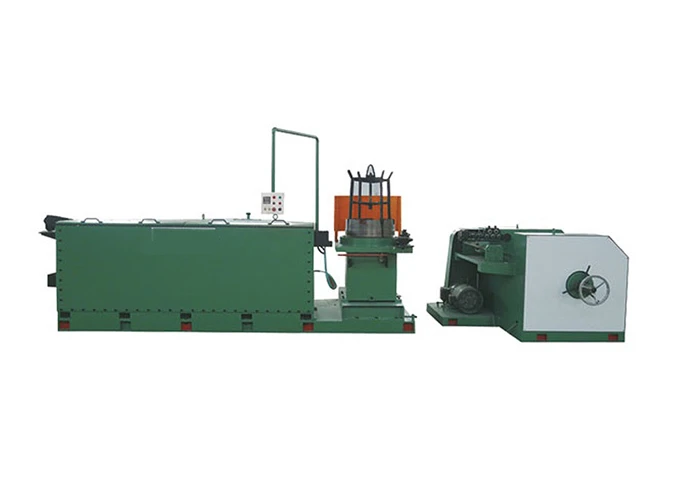

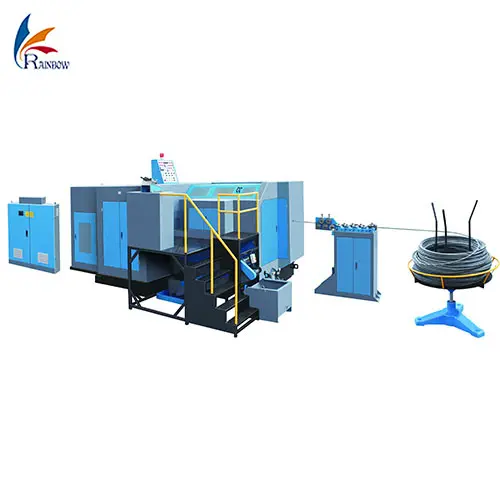

The Role of Turnover Wet Wire Drawing Machine in Wire Manufacturing Industry

The Turnover Wet Wire Drawing Machine plays a crucial role in the wire manufacturing industry, especially when it comes to processing wires that require precision and high-quality surface finishes. Its primary functions and roles include:

1. Wire Reduction: The primary function of the Turnover Wet Wire Drawing Machine is to reduce the diameter of wires. It achieves this by pulling the wire through a series of drawing dies that gradually decrease the wire's diameter. This reduction process is essential for producing wires of various sizes to meet specific industry requirements.

2. Precision Drawing: This steel wire drawing machine is known for its ability to provide precise control over the reduction of wire diameter. Precision is essential in industries like electronics, where wires must meet strict tolerances for conductivity and size.

3. Surface Finish Improvement: The wet drawing process, facilitated by this machine, helps improve the surface finish of the wire. It smoothens the wire's exterior, resulting in a high-quality finish. This is crucial in applications where the wire's surface must be free of defects or imperfections.

4. Material Hardening: The drawing process not only reduces the wire's diameter but also hardens the material. This is especially beneficial for wires used in applications where strength and durability are critical, such as automotive and construction.

5. Intermediate Coiling: The steel wire drawing machine is often equipped with a coiling system that collects and packages the drawn wire onto spools or drums. This ensures the wire is efficiently processed and prepared for subsequent manufacturing steps or storage.

6. Versatile Use: The Turnover Wet Wire Drawing Machine can process various materials, including different metals and alloys, depending on the industry's needs. It is used for drawing ferrous and non-ferrous materials.

7. Quality Assurance: The steel wire drawing machine contributes to the consistent quality of wire products. The precise drawing process ensures that the final wire meets the required specifications for diameter, surface finish, and mechanical properties.

In summary, the Turnover Wet Wire Drawing Machine is essential in wire manufacturing to produce wires with controlled diameters, high precision, and superior surface finishes. Its role in enhancing the quality, strength, and versatility of wires makes it a critical component in industries such as electronics, automotive, telecommunications, and construction.

English

English français

français Español

Español русский

русский português

português