Advantages of Inverted Vertical Wire Drawing Machine

Inverted vertical wire drawing machines offer several advantages in the wire manufacturing and processing industry. Here are four key advantages of using these machines:

1. Space Efficiency: Inverted vertical wire drawing machines are designed to take up less floor space compared to horizontal machines. Their compact and vertical layout allows for more efficient use of available space in manufacturing facilities.

2. Enhanced Wire Quality: These machines are capable of producing wire with improved quality and surface finish. The vertical design minimizes the risk of wire entanglement and scratching during the drawing process, resulting in smoother and higher-quality wire.

3. Energy Efficiency: Inverted vertical wire drawing machines often have efficient motor and drive systems that reduce energy consumption. The vertical configuration also minimizes friction and energy losses, making them more energy-efficient compared to some horizontal counterparts.

4. Ease of Maintenance: Access to components and maintenance tasks is generally more convenient with inverted vertical machines. Maintenance personnel can easily reach and service parts, reducing downtime and ensuring that the machine operates optimally.

These advantages make inverted vertical wire drawing machines a preferred choice for wire manufacturers looking to optimize space, improve wire quality, reduce energy consumption, and streamline maintenance processes. Get more information about wire drawing machine manufacturer.

How Does Inverted Wire Drawing Machine Work?

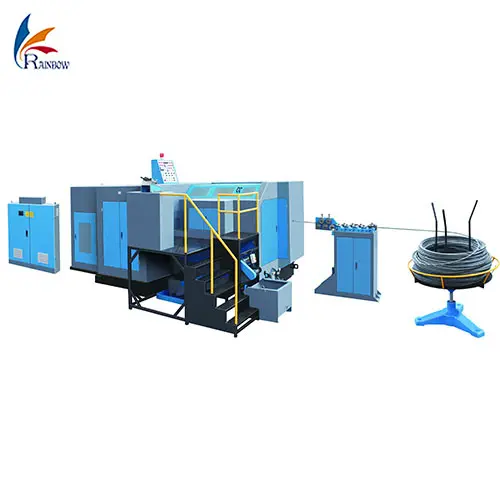

The raw material enters the wire drawing machine through the wire inlet, and is then stretched through the wire drawing reel to reduce its diameter and increase its length. During the drawing process, the speed and drawing force of the drawing drum can be adjusted as needed to achieve the desired drawing effect. Finally, the drawn wire is discharged through the outlet.

The drum of the inverted wire drawing machine usually adopts the inverted structure, that is, the axis of the drum is perpendicular to the ground. This structure can make the reel better withstand the tension during the drawing process, and also facilitate the discharge and collection of the wire. In addition, the inverted wire drawing machine is usually equipped with an automatic control system, which can realize automatic production and improve production efficiency and product quality.

Instructions and Maintenance of Vertical Wire Drawing Machine

Preparation: Before operation, check the power supply and ensure proper lubrication of moving parts. Verify wire specifications and adjust drawing dies accordingly.

Startup and Operation: Gradually start the machine, monitoring parameters such as drawing speed and tension. Ensure wire protection to prevent scratches or bends during the process.

Post-Operation: After completing the task, gradually reduce speed, turn off the machine, and clean the work area. Record production data for future reference.

Daily Maintenance:

Keep the machine and surrounding area clean.

Inspect electrical connections and lubricate moving parts.

Weekly Maintenance:

Check the tension of the conveyor and drawing belts.

Ensure the machine operates safely and correctly.

Periodic Maintenance:

Replace worn components like belts and bearings as needed.

Calibrate machine settings to maintain operational accuracy.

Safety Checks: Regularly inspect safety devices to ensure they are functioning properly and follow safety protocols during operation.

English

English français

français Español

Español русский

русский português

português