With the rapid development of the manufacturing industry, improving production efficiency, reducing production costs, and ensuring product quality have become key to enterprise competition. In this context, hot nut forging machines, as a kind of efficient and precise production equipment, gradually occupy a place in the production line. In this article, we will discuss in detail the advantages of using hot nut forging machines in production lines from four aspects.

Improvement of Surface Quality

Hot forging is a kind of forging process under high temperature, which can make the metal material become soft and easy to deform, thus effectively improving the roughness and unevenness of the surface of the parts. Hot forging provides more precise surface shapes and accuracy than other molding processes, and offers significant advantages in terms of corrosion and wear resistance and surface quality.

Enhanced Mechanical Properties

The hot nut forging machine can forge materials at high temperatures, thereby rearranging their basic lattice structure. Grain coarsening, morphology changes, and dislocation density are reduced, thus improving the performance of the parts in terms of low-cycle fatigue, high-cycle fatigue, durability, and toughness. Because the grain size of the material becomes finer during hot forging, parts exhibit more uniform and reliable mechanical properties.

Improved Cost-Effectiveness

The production process of a hot nut forging machine requires relatively short time, and the production efficiency is much higher than the traditional processing and manufacturing process. It can effectively reduce cost, improve efficiency and quality, and meet the requirements of high quality, high efficiency, and high profit of the enterprise. In addition, because the cost of hot forging is relatively low, it can bring huge profits for enterprises.

Improve Production Efficiency

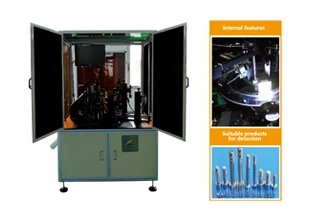

Adopting advanced forging technology, the hot nut forging machine is able to complete the nut forming process in a fast and continuous manner. Compared with traditional processing methods, the fastener equipment eliminates the need for multiple process changes and significantly reduces the production cycle. At the same time, the high degree of automation and intelligent design of the forging machine can realize the precise control of the production process, which further improves the production efficiency.

In summary, the application of hot nut forging machines in production lines has many advantages. The introduction of the hot nut forging machine is certainly a wise choice for companies wishing to achieve greater success in the manufacturing market. Harbin Rainbow Technology Co., Ltd is one of the biggest fastener equipment dealers and manufacturers in China. We sincerely look forward to working with you.

English

English français

français Español

Español русский

русский português

português