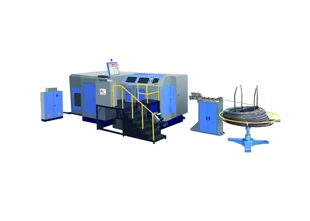

A CNC thread rolling machine is a machine used to create threads and is commonly used in industrial production. It forms threads by rolling material between two rotating metal wheels. It not only improves the efficiency of workers in cutting steel bars but also optimizes the accuracy of thread density through an easy-to-understand system combined with process tools. This improves the rapid development of the industries and does not delay the overall progress of the project due to lack of labor.

Understanding CNC Thread Rolling Machine

CNC thread rolling machine is a multi-functional cold extrusion forming machine that can thread, straighten, and twill roll workpieces. The machine has a safe and reliable actuation and control system that allows each work cycle to be selected from manual, semi-automatic, and automatic modes. CNC thread rolling machine can effectively improve the intrinsic and surface quality of the workpiece, and is an ideal process with high efficiency, energy saving, and low consumption.

High Precision Machining

CNC thread rolling machine can realize micron-level machining accuracy through advanced CNC control system. Whether it is threading, knurling, or rolling, CNC thread rolling machine can guarantee the size and shape accuracy of the processed parts. This high-precision machining not only improves the overall quality of the product, but also meets the demanding needs of various industries for high-precision parts.

Improved Processing Efficiency

CNC thread rolling machine adopts precise servo motors and transmission system to realize high-precision positioning during the machining process of workpieces. Through pre-set machining programs, the CNC thread rolling machine is able to automatically complete the machining process of the workpiece without human intervention. This highly accurate positioning not only improves machining efficiency, but also reduces the error rate of manual operation. Learn more details from the thread rolling machine manufacturer.

Flexible Machining Capabilities

The CNC thread rolling machine has the flexibility to adapt to the machining of different materials and shapes of workpieces. By changing different tools and fixtures, it can accomplish a wide range of machining tasks, from simple to complex. This flexibility makes CNC thread rolling machine widely used in many industries and become an indispensable equipment in manufacturing industry.

To sum up, CNC thread rolling machine plays an increasingly important role in manufacturing industry with its advantages of high precision, high accuracy, flexible and changeable machining capability, and high efficiency, etc. Harbin Rainbow Technology Co., Ltd is one of the biggest fastener equipment dealers and manufacturers in China. We have more than 30 years experiences in supplying all kinds of fastener equipment to customers all over the world. If you are interested, please contact us.

English

English français

français Español

Español русский

русский português

português